Industrial Strength Solutions: Advanced Zinc Nickel Plating and Precision Shot Peening Excellence

Their integrated approach combines zinc nickel plating company capabilities with complementary finishing services, providing clients with comprehensive solutions that address complex surface treatment challenges.

In demanding industrial environments, component durability depends entirely on surface preparation and protective treatment. Selecting a trusted zinc nickel plating company and reliable shot peening services are fundamental decisions that impact performance, longevity, and overall project success. These surface treatment processes work synergistically to shield critical parts from corrosion, fatigue failure, and operational stress.

Corrosion Resistance and Performance: The Role of a Professional Zinc Nickel Plating Company

Zinc nickel plating represents one of the most effective barriers against corrosion in harsh industrial applications. A dedicated zinc nickel plating company applies sophisticated electroplating techniques that deposit uniform, protective coatings on ferrous and non-ferrous substrates. This specialized process creates a dense metallic layer that resists saltwater, humidity, and chemical exposure far better than conventional zinc plating alone. Industries ranging from aerospace to automotive rely on zinc nickel plating company expertise to ensure components survive extended service life in aggressive environments. The investment in professional plating services delivers measurable returns through extended equipment reliability and reduced maintenance costs over years of operation.

Enhancing Strength and Reliability: The Impact of Shot Peening Services

Shot peening services strengthen components at the molecular level through controlled surface bombardment. This mechanical process compresses the outer material layers, creating a protective residual stress field that dramatically increases fatigue resistance. When precision-engineered components face cyclic loading and vibration stress, shot peening services provide the enhancement needed to prevent crack initiation and catastrophic failure. The process works particularly well when combined with other surface treatments, amplifying the overall protection against operational wear. Manufacturing professionals understand that investing in quality shot peening services translates directly into extended component lifespan, improved safety performance, and significant cost savings through reduced downtime and replacement frequency.

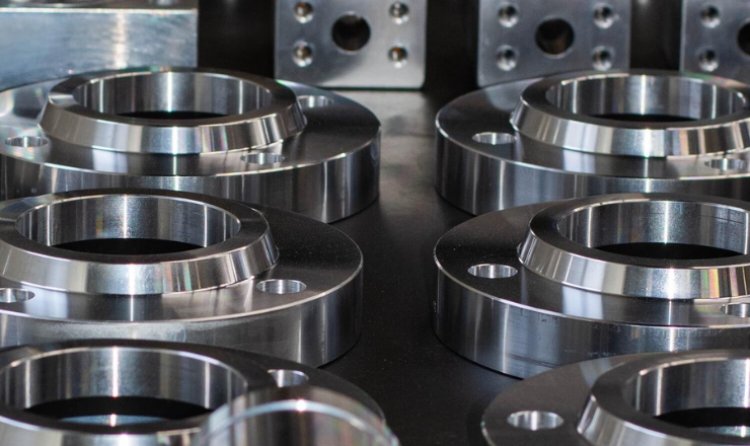

Peregrine Metal Finishing: Precision Engineering and Surface Excellence

Peregrine Metal Finishing stands apart through unwavering commitment to technical excellence and customer success. As a premier zinc nickel plating company, they employ state-of-the-art electroplating equipment operated by certified technicians who maintain rigorous quality standards throughout every project. Their shot peening services utilize advanced intensity monitoring and documented process controls to ensure consistent results that exceed industry specifications. Whether clients require single components or high-volume production runs, Peregrine Metal Finishing delivers precision coating consistency, precise surface hardness targets, and comprehensive material traceability. Their integrated approach combines zinc nickel plating company capabilities with complementary finishing services, providing clients with comprehensive solutions that address complex surface treatment challenges.

Conclusion: Investing in Durability and Performance Excellence

Industrial components demand more than basic protection they require engineered durability that sustains performance across decades of challenging operation. Partnering with an experienced zinc nickel plating company and utilizing professional shot peening services demonstrates commitment to quality, safety, and long-term value creation. Peregrine Metal Finishing provides the technical expertise, advanced equipment, and quality assurance necessary to keep industrial operations running reliably, protecting investments and enabling business success through superior surface treatment solutions.

jacksonjk

jacksonjk